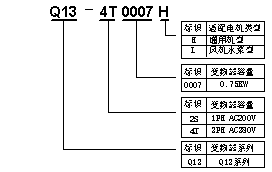

Q13 series frequency converter is a multi-functional, high-performance vector inverter, using the most professional motor drive technology, safe and reliable, optional XSP05 panel (potentiometer) and XSP10 panel (LCD), more convenient operation; Suitable for electronic equipment, packaging, printing, machine tools, hardware, engineering and other occasions.

Single phase 220V 0.75-5.5KW Three-phase 380V 0.75-200KW

|

Projects |

Specifications |

||

|

Basic control function |

Maximum frequency |

Vector Control: 0 ~ 500Hz ZV/F control: 0 ~ 500Hz

|

|

|

Carrier Frequency |

0.5kHz~16kHz The carrier frequency can be adjusted automatically according to the load characteristics. |

||

|

Input frequency resolution

|

Digital setting: 0.01 Hz analog setting: MAX frequency × 0.025%

|

||

|

Control Mode |

Open-loop vector control (no PG) Closed-loop vector control (with PG) V/f control |

||

|

Starting Torque |

H: 0.5 Hz/150% (no PG) ; 0hz/180% (PG) ; L: 0.5 Hz/100%

|

||

|

Speed range |

1:100(no PG) |

1:1000 (There is PG) |

|

|

Speed stability accuracy |

±0.2% (no PG) |

±0.02% (There is PG) |

|

|

Torque control accuracy |

±5% (There is PG) |

||

|

Overload capacity |

Model H: 150% rated current 60s; 180% rated current 3s. Model L: 120% rated current 60s; 150% rated current 3s.

|

||

|

Torque Boost |

Automatic torque improvement, manual torque improvement of 0.1% ~ 30.0% |

||

|

V/f curve |

Three types: straight line; multi-point; n-power V/F curve (1.2 power, 1.4 power, 1.6 power, 1.8 power, 2 power)

|

||

|

V/F separation |

2 ways: full separation, half separation |

||

|

Acceleration and deceleration curves |

Linear or s-curve acceleration and deceleration mode. Four kinds of acceleration and deceleration time, acceleration and deceleration time range 0.0 ~ 6500.0 s

|

||

|

DC brake |

DC brake frequency: 0.00 hz-maximum frequency Braking time: 0.0 S ~ 36.0 s Braking current: 0.0% ~ 100.0% |

||

|

Point Control |

Tap frequency range: 0.00 hz-50.00 Hz. The acceleration and deceleration time is 0.0 s ~ 6500.0 s. |

||

|

Simple PLC, multi-speed operation |

Through the built-in PLC or control terminal to achieve up to 16 segments of speed operation |

||

|

Projects |

Specifications |

||

|

|

Built-in PID |

The process control closed-loop control system can be conveniently realized |

|

|

Automatic voltage regulation (AVR) |

When the network voltage changes, can automatically maintain the output voltage constant |

||

|

Overvoltage and overcurrent stall control |

Automatic limit of current and voltage during operation to prevent frequent overcurrent and overvoltage trip |

||

|

Fast current limiting function |

Minimizes overcurrent failure and protects the converter from normal operation |

||

|

Torque limitation and control

|

“Excavator” features, the operation of torque automatic limit to prevent frequent overcurrent trip; closed-loop vector mode can achieve torque control |

||

|

Personalized features |

Superior performance |

Asynchronous motor and synchronous motor are controlled by high performance current vector control technology |

|

|

All the time |

The reduction of the voltage compensated by the load feedback energy can keep the inverter running for a short time during the transient power failure |

||

|

Fast current limiting |

Avoid frequency converter frequent over-current fault |

||

|

Timing control |

Timing control function: set time range 0.0 min-6000.0 min |

||

|

Means of communication |

Support: Rs -485 |

||

|

Protective function |

On-motor short-circuit detection, input and output protection, over-current protection, over-voltage protection, under-voltage protection, over-heat protection, overload protection |

||

|

Run |

Run the instruction channel |

The Operation Panel is given, the control terminal is given and the serial communication port is given. You can switch between them in a number of ways

|

|

|

Frequency source |

Multiple frequency sources: digital set, analog voltage set, analog current set, pulse set, serial port set. You can switch between them in a number of ways |

||

|

Auxiliary frequency source |

10 auxiliary frequency sources. The auxiliary frequency fine-tuning and frequency synthesis can be flexibly realized |

||

|

Input Terminal |

Standard: 5 digital input terminals, 1 for high-speed pulse input up to 100kHz 2 analog input terminals, 1 for 0-10V voltage input only, 1 supports 0-10V voltage input or 4-20mA current input

|

||

|

Output Terminal |

1 high-speed pulse output terminal (optional open-circuit collector type) , support 0-100kHz square wave signal output 1 digital output terminal 1 relay output terminal 2 analog output terminal, support 0-20mA current output or 0-10V voltage output

|

||

|

Frequency converter model |

Quota output power (KW) |

Input Current (A)

|

Output Current(A) |

ADAPTOR motor(KW) |

|

|

Single-phase input power supply: 220V (-15% ~ + 15%) , 50/60Hz |

|||||

|

Q13-2S0007H |

0.75 |

10.5 |

4.5 |

0.75 |

|

|

Q13-2S0015H |

1.5 |

14.5 |

7.0 |

1.5 |

|

|

Q13-2S0022H |

2.2 |

21.4 |

10.0 |

2.2 |

|

|

Q13-2S0037H |

3.7 |

35.9 |

17.0 |

3.7 |

|

|

Q13-2S0055H |

5.5 |

42 |

25 |

5.5 |

|

|

Three-phase input power supply: 380V (-15% ~ + 15%) , 50/60Hz |

||||

|

Q13-4T0007H |

0.75 |

3.5 |

2.5 |

0.75 |

|

Q13-4T0015H |

1.5 |

6.2 |

4.0 |

1.5 |

|

Q13-4T0022H |

2.2 |

9.2 |

5.5 |

2.2 |

|

Q13-4T0040H |

4.0 |

14.9 |

9 |

4.0 |

|

Q13-4T0055H |

5.5 |

21.5 |

13 |

5.5 |

|

Q13-4T0075H |

7.5 |

28.9 |

18 |

7.5 |

|

Q13-4T0110H |

11 |

39.0 |

24 |

11 |

|

Q13-4T0150H |

15 |

50.3 |

33 |

15 |

|

Q13-4T0180H |

18 |

60.0 |

38 |

18 |

|

Q13-4T0220H |

22 |

69.3 |

45 |

22 |

|

Q13-4T0300H |

30 |

86 |

60 |

30 |

|

Q13-4T0370H |

37 |

104 |

75 |

37 |

|

Q13-4T0450H |

45 |

124 |

91 |

45 |

|

Q13-4T0550H |

55 |

150 |

112 |

55 |

|

Q13-4T0750H |

75 |

160 |

150 |

75 |

|

Q13-4T0900H |

90 |

180 |

175 |

90 |

|

Q13-4T1100H |

110 |

196 |

210 |

110 |

|

Q13-4T1320H |

132 |

232 |

250 |

132 |

|

Q13-4T1600H |

160 |

282 |

300 |

160 |

|

Q13-4T2000H |

200 |

352 |

415 |

200 |

|

Voltage level |

Type of aircraft |

Frequency converter model |

Shape and mounting dimensions (mm) |

||||||

|

W |

H |

D |

W1 |

H1 |

D1 |

Mounting holes |

|||

|

220V |

A |

Q13-2S0007H |

118 |

185 |

145 |

105 |

173 |

45 |

5 |

|

Q13-2S0015H |

|||||||||

|

Q13-2S0022H |

|||||||||

|

B |

Q13-2S0037H |

130 |

220 |

181 |

116 |

208 |

60 |

5 |

|

|

Q13-2S0055H |

|||||||||

|

380V |

A |

Q13-4T0007H |

118 |

185 |

145 |

105 |

173 |

45 |

5 |

|

Q13-4T0015H |

|||||||||

|

Q13-4T0022H |

|||||||||

|

C |

Q13-4T0040H |

118 |

185 |

181 |

105 |

173 |

60 |

5 |

|

|

B |

Q13-4T0055H |

130 |

220 |

181 |

116 |

208 |

60 |

5 |

|

|

Q13-4T0075H |

|||||||||

|

D |

Q13-4T0110H |

208 |

322 |

192 |

190 |

306 |

112 |

7 |

|

|

Q13-4T0150H |

|||||||||

|

Q13-4T0180H |

|||||||||

|

E |

Q07-4T0220H |

220 |

380 |

190 |

185 |

404 |

138 |

7 |

|

|

Q07-4T0300H |

|||||||||

|

F |

Q07-4T0370H |

256 |

430 |

202 |

196 |

450 |

153 |

7 |

|

|

Q07-4T0450H |

|||||||||

|

G |

Q07-4T0550H |

320 |

575 |

233 |

220 |

553 |

101 |

10 |

|

|

Q07-4T0750H |

|||||||||

|

H |

Q07-4T0900H |

404 |

615 |

249 |

270 |

590 |

110 |

10 |

|

|

Q07-4T1100H |

|||||||||

|

I |

Q07-4T1320H |

466 |

745 |

325 |

343 |

715 |

184 |

12 |

|

|

Q07-4T1600H |

|||||||||

|

J |

Q07-4T2000H |

540 |

890 |

377 |

370 |

856 |

205 |

14 |

|

Keypad outside pull tray hole size:110mm*74mm